The Necessary Attributes of Excavator That Make It a Must-Have Device

Excavators are essential in the construction and landscape design sectors. Their functional add-ons allow for a range of tasks, from excavating to demolition. Furthermore, they boast premium digging depth and reach, powered by durable engines. Driver comfort and portable designs enhance usability in numerous settings. What absolutely establishes excavators apart are their advanced hydraulic systems and resilience. Recognizing these features can clarify why they are taken into consideration vital devices on any type of work website.

Flexible Accessories for Improved Functionality

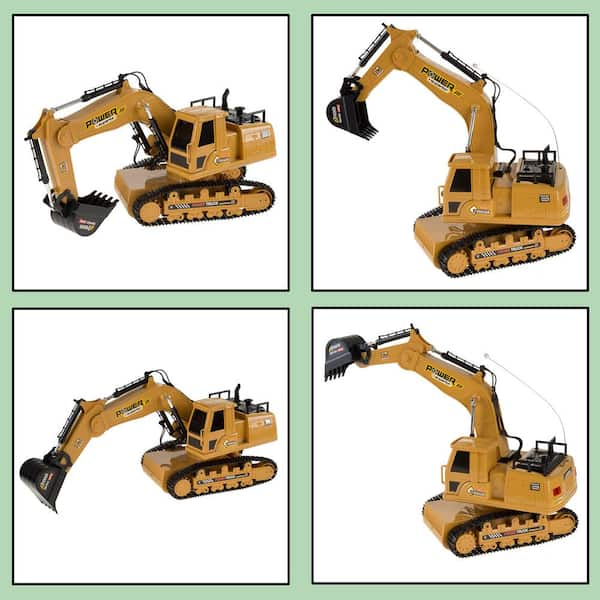

Excavators are effective makers on their very own, the addition of flexible accessories substantially boosts their functionality. These accessories change a standard excavator into a multi-purpose device, appropriate for a range of tasks. Containers, for instance, been available in various sizes and shapes, allowing operators to dig, scoop, and relocate materials efficiently. Hydraulic thumbs can be added for boosted gripping and handling of bulky things, such as logs or rocks.Furthermore, specialized add-ons like breakers and augers enable drilling and demolition job, broadening the excavator's utility on building websites. remote control excavator. Grapples are another alternative, perfect for sorting and moving particles. This adaptability not only enhances productivity yet additionally reduces the requirement for numerous equipments, conserving time and expenses. By gearing up excavators with the right add-ons, drivers can tackle varied tasks, making them crucial in the building and construction market

Superior Excavating Deepness and Reach

Excavators are designed with premium excavating depth and reach, allowing them to navigate in tight rooms and access hard-to-reach areas. This capability is important for different building and excavation jobs, where traditional machinery might fall short. With adjustable boom arms and extendable tracks, excavators can easily browse irregular surface while maintaining stability.The digging depth can vary substantially among models, frequently ranging from 10 to 25 feet, depending upon the design and purpose. This feature makes it possible for drivers to dig deep into structures, trenches, and various other deep structures successfully. Furthermore, the reach of an excavator enables exact excavating and material handling without repositioning the equipment often, saving time and labor costs.Ultimately, the remarkable excavating deepness and reach of excavators make them crucial for specialists seeking to complete complex tasks with accuracy and efficiency. Their adaptability boosts efficiency on work websites, showcasing them as a vital tool in modern-day construction.

Powerful Engine Performance

When it involves effectiveness and productivity on building websites, effective engine efficiency plays an essential function in the capabilities of an excavator. A robust engine produces significant horse power, enabling the maker to tackle durable tasks easily - remote control excavator. This toughness equates right into faster cycle times, allowing drivers to total tasks a lot more quickly.Additionally, powerful engines offer the required torque to handle challenging terrains and varied loads, ensuring that the excavator can carry out efficiently under various problems. Whether it is lifting, digging, or moving products, the engine's performance straight influences the overall operational effectiveness of the machine.Furthermore, innovations in engine innovation have actually brought about boosted fuel performance, lowering operational prices while preserving power result. Ultimately, the engine's performance acts as the foundation of an excavator, verifying its status as an indispensable tool in the building and construction market

Advanced Hydraulic Equipments

Enhanced Lifting Ability

A significant enhancement in lifting capability can be credited to advanced hydraulic systems located in modern excavators. These systems make use of high-pressure fluid to produce higher force, allowing drivers to raise much heavier loads with simplicity. The design behind these hydraulics guarantees peak efficiency, providing an outstanding power-to-weight proportion that boosts general performance. Consequently, excavators can tackle demanding jobs, such as raising large materials or equipment, without endangering stability. Furthermore, the robust design of hydraulic parts adds to enhanced sturdiness and integrity, making them ideal for different construction atmospheres. This boosted lifting ability not just reduces the moment required for jobs yet additionally minimizes the requirement for additional machinery, showing crucial for both productivity and cost-effectiveness in the building sector.

Improved Accuracy Control

Although conventional excavators often battled with accuracy, contemporary hydraulic systems have transformed control systems, enabling drivers to perform tasks with exceptional accuracy. These innovative systems utilize proportional control shutoffs that enable for smoother and much more responsive movements, significantly decreasing the margin for error. Operators can now carefully tune the excavator's activities, making it easier to navigate tight spaces and handle delicate materials. Enhanced feedback systems additionally home educate operators of real-time performance, guaranteeing ideal control in between the equipment and operator. This raised precision not just boosts efficiency but likewise enhances safety and security on task sites, minimizing the risk of accidents. As an outcome, modern-day excavators equipped with advanced hydraulic systems are very useful devices for building and construction and excavation jobs calling for careful accuracy.

Driver Comfort and Presence

Operator convenience and exposure are essential elements in the layout of contemporary excavators (remote control excavator). Functions such as ergonomic seat layout, enhanced presence choices, and efficient control formats significantly boost the operator's experience and productivity. Focusing on these elements warranties that drivers can function successfully and securely in numerous problems

Ergonomic Seat Style

Comfort and visibility are extremely important in excavator style, with the ergonomic seat playing a crucial role in boosting the driver's experience. An ergonomic seat is engineered to support the operator's body, lowering tiredness throughout lengthy hours of procedure. Adjustable functions, such as seat height, backrest angle, and lumbar support, accommodate individual preferences and advertise optimal posture. These adjustments enhance comfort and make it possible for the driver to keep emphasis on jobs without pain. Additionally, a well-designed seat can offer much better side assistance, enabling smoother handling when the excavator is in operation. This thoughtful style not only increases efficiency but also adds to general security, making sure that drivers can execute their duties properly and effectively.

Enhanced Presence Attributes

The style of an excavator prolongs past just the seat, with enhanced presence features playing a considerable duty in driver comfort and total security. Big home windows and tactically located mirrors provide drivers with a clear view of their environments, lessening blind areas. This design consideration permits better spatial awareness, which is essential in active work environments. In enhancement, lots of excavators integrate rearview cameras and advanced monitoring systems that help operators in navigating limited areas. The integration of these presence includes not only promotes security but likewise decreases operator fatigue by allowing less complicated monitoring of workspace. Ultimately, enhanced visibility adds to extra effective operations and assists ensure that excavators can do their jobs efficiently and securely.

Control Design Effectiveness

While maneuvering complex job websites, an effective control format greatly boosts both driver convenience and exposure. A well-designed control configuration assurances that operators can access important features with very little effort, lowering tiredness during long hours. Ergonomic joystick placements and this intuitive switch plans permit smooth operation, allowing drivers to keep concentrate on the task at hand. In addition, clear exposure of both the work area and the control panel is important for safety and accuracy. Modern excavators commonly include adjustable seats and control setups to suit different driver preferences, additionally boosting comfort. Inevitably, a thoughtfully made control layout not only boosts productivity however additionally fosters a more secure working atmosphere by enabling drivers to respond swiftly to altering conditions.

Compact Style for Urban Environments

As city construction sites often face room constraints, a small style becomes vital for excavators operating in these environments. These makers are engineered to browse tight rooms, enabling efficient ability to move in congested task sites. A reduced footprint enables them to work carefully to existing structures, minimizing disturbance and taking full advantage of productivity.The small style usually consists of much shorter tracks and a tighter turning distance, helping with operation in narrow streets and confined locations. Additionally, lightweight materials add to reduce of transportation, making it less complex to move the excavator from one area to one more within the city landscape.Additionally, several small excavators are equipped with attributes such as functional attachments and extendable arms, improving their performance while maintaining a small size. This versatility allows drivers to deal with a range of tasks, from digging to demolition, all while suitable flawlessly into the restrictions of urban settings.

Longevity and Upkeep Considerations

Resilience stands as a necessary consider the efficiency and durability of excavators, particularly sought after city environments. These equipments go through rigorous conditions, consisting of varying soil types, severe temperatures, and high-frequency use. High-grade products and robust construction are required for making sure that excavators can stand up to these obstacles without endangering functionality.Regular maintenance is equally vital in preserving resilience. Scheduled assessments, timely oil adjustments, and the replacement of worn components add substantially to an excavator's life-span. Operators should also take note of hydraulic systems, tracks, and undercarriages, as these parts commonly bear the burden of wear and tear.Investing in long lasting excavators with substantial maintenance plans boosts integrity and decreases downtime, eventually causing boosted productivity on building sites. Consequently, recognizing the interplay between durability and maintenance is essential for any individual taking into consideration the procurement of an excavator for urban jobs.

Regularly Asked Inquiries

Exactly How Do Excavators Contrast to Various Other Construction Devices?

Excavators stand out among building devices as a result of their flexibility, enabling jobs such as grading, digging, and lifting. Compared to others, their hydraulic capabilities use better efficiency and power, making them indispensable on different task websites.

What Security Features Are Included in Modern Excavators?

Modern excavators incorporate various safety features, consisting of rollover defense systems, alarm systems, and advanced exposure enhancements. These elements interact to reduce dangers, making sure operator safety and security while enhancing performance on building websites and various other demanding settings.

Can Excavators Be Utilized in Winter Months Conditions?

Excavators can indeed be utilized in winter months problems, supplied they are outfitted with ideal winter add-ons and preventative measures are taken. Correct maintenance and adjustments enhance their efficiency, making certain efficient operation despite tough weather condition situations.

What Is the Typical Life Expectancy of an Excavator?

The average lifespan of an excavator typically ranges from 7,000 to 10,000 hours of procedure. This duration can significantly depend upon upkeep methods, operating problems, and the particular design's toughness and design functions.

Just how Do I Select the Right Excavator Dimension for My Job?

Choosing the ideal excavator size entails reviewing project scope, website conditions, and product types. Consider elements like reach, deepness demands, and weight capacity to ensure maximum efficiency and safety and security during procedure. Size matters substantially in job success. Additionally, the reach of an excavator permits for exact excavating and product handling without repositioning the equipment often, conserving time and labor costs.Ultimately, the exceptional excavating depth and reach of excavators make them essential for experts seeking to finish complex jobs with precision and performance. Convenience and presence are vital in excavator layout, with the ergonomic seat playing a crucial function in boosting the driver's experience. The style of an excavator expands beyond just the seat, with enhanced exposure functions playing a considerable duty in operator comfort and total security. Modern excavators often incorporate adjustable seats and control settings to suit click reference different driver choices, additionally boosting comfort. Lightweight materials contribute to reduce of transportation, making it easier to relocate the excavator from one area to another within the urban landscape.Additionally, many compact excavators are furnished with features such as flexible add-ons and extendable arms, enhancing their performance while keeping a tiny size.